Cosinus Slide® Joint

Why Cosinus Slide®?

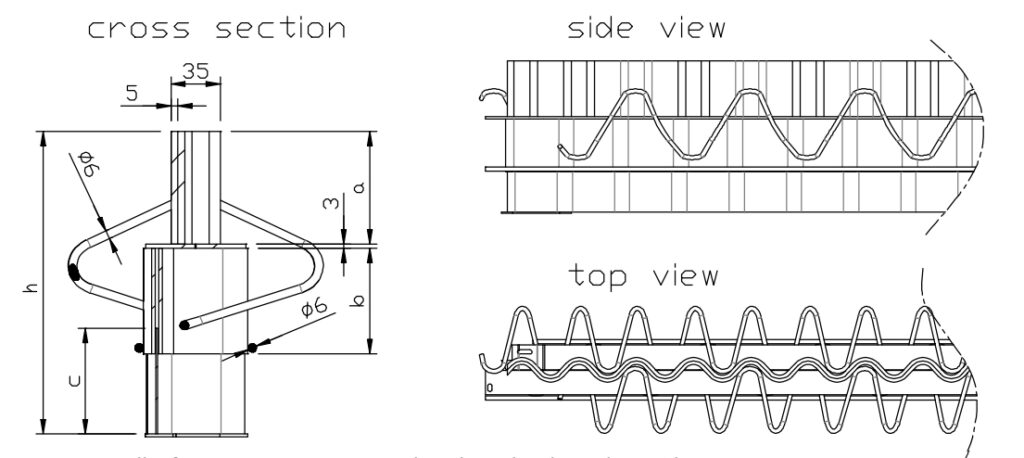

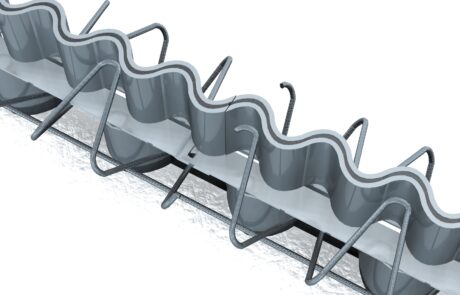

First and most visible: It has the only and unique “double slide” continuous load transfer on the market. The famous sinus wave shape on top of the floor avoids vibrations and neutralizes wheel impact. Second, less visible, yet most important: It has the only and unique “double sinus slide” continuous load transfer system on the market. A second sinus wave in the middle of the floor, in combination with the continuous 3D anchorage system, creates the best performing and highly efficient load transfer system over and throughout the joint. It achieves this without using the limited performance of dowel technology from inferior copies

As a result of combining these two advantages:

As a result of combining these two advantages:

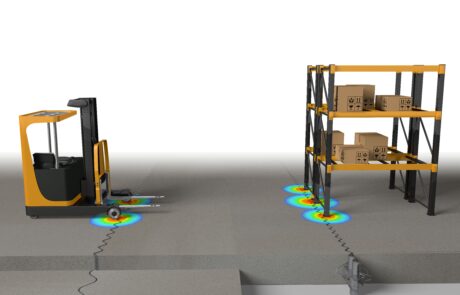

- Best Load-transfer system: no limitation on where you place your racking system

- Decreased floor thickness, while maintaining the strength

- Optimal operational efficiency

- Less expense in the future on armoured joints and concrete floor maintenance

- Less expense in the future on warehouse equipment maintenance (forklift, robots, manual forklift, hand pallet jack)

- Continuous 3D anchorage system (patented technology)

- High level of comfort experienced by forklift operators

- Avoids production downtime during concrete floor maintenance.

| Profile Type | Slab Thickness h [mm] | Sinus a (mm) |

Cosinus b (mm) |

Adjust. plate c (mm) |

Weight (kg/m) |

Weight (kg/pcs) |

Quantity (pcs) |

Pallet quantity (m) |

Gross Weight (kg) | Pallet Height (m) |

| 90/120 | 90 – 120 | 50 | 35 | 40 | 9,94 | 25,85 | 7 | 187,2 | 1910 | 1,15 |

| 115/150 | 115 – 150 | 60 | 50 | 50 | 11,92 | 30,99 | 56 | 145,6 | 1790 | 1,08 |

| 160/215 | 160 – 215 | 80 | 75 | 75 | 15,16 | 39,42 | 48 | 124,8 | 1950 | 1,24 |

| 205/300 | 205 – 300 | 80 | 120 | 120 | 17,60 | 45,76 | 28 | 72,8 | 1340 | 1,08 |

| 300/400 | 300 – 400 | 116 | 170 | 170 | 23,72 | 61,67 | 21 | 54,6 | 1350 | 1,17 |

Technical information and instructions: