ArmoTec

Betotrade OÜ’s product range has been expanded with a new and cost-effective Armotec macropolymer fiber.

Armotec is suitable for use in floor constructions, like other market available macrofibers, in applications where high loads are not applied, such as apartment building flooring, public buildings, commercial spaces, etc. It is also suitable for constructions where corrosion resistance or dielectricity is important. Armotec is also suitable for use in agriculture building constructions.

The best price and quality ratio of macrofiber.

Betotrade OÜ is capable of performing load bearing calculations to find accurate floor parameters.

BarChip MQ 58

The best technical macrofiber on the Estonian market. It has an environmental certificate (EPD), which allows BarChip MQ 58 to be used according to the LEED or BREEAM assessment methods.

BarChip MQ 58 provides the best post-crack strength properties among the available macrofibers on the market for concrete. Lower dosages compared to competitors.

Finishing is easy to perform as the fiber’s surface rise is minimal, even with high dosages.

Betotrade OÜ is capable of performing load-bearing calculations.

Betotrade OÜ Advantages of Macrofibers:

- Non-corrosive

- Dielectric

- Easy to transport, store, dose

- Smaller CO2 footprint

- EPD certificate

- Possible to perform load-bearing calculations

Applications of Macrofibers:

- Apartment building flooring

- Agricultural building constructions

- Parking garages

- Commercial spaces

- Acid-resistant constructions

Comparison with Steel Fibers:

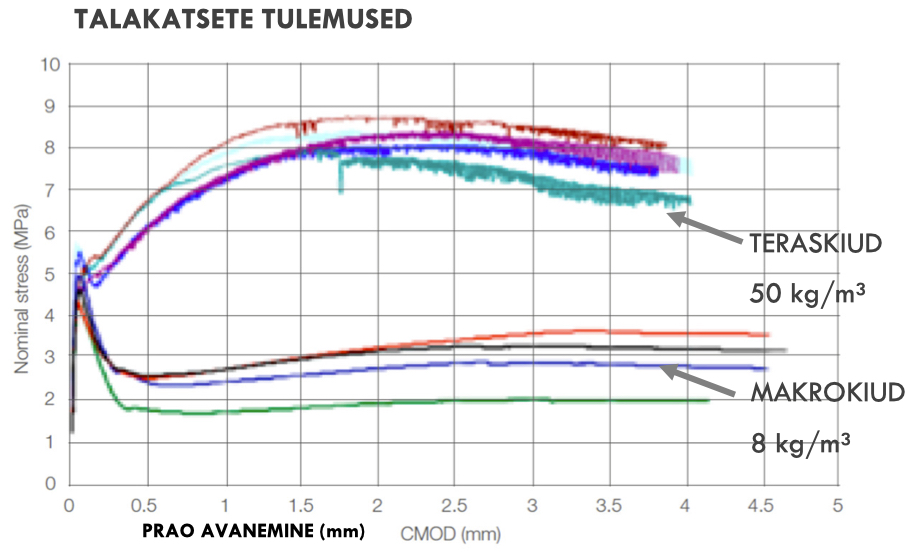

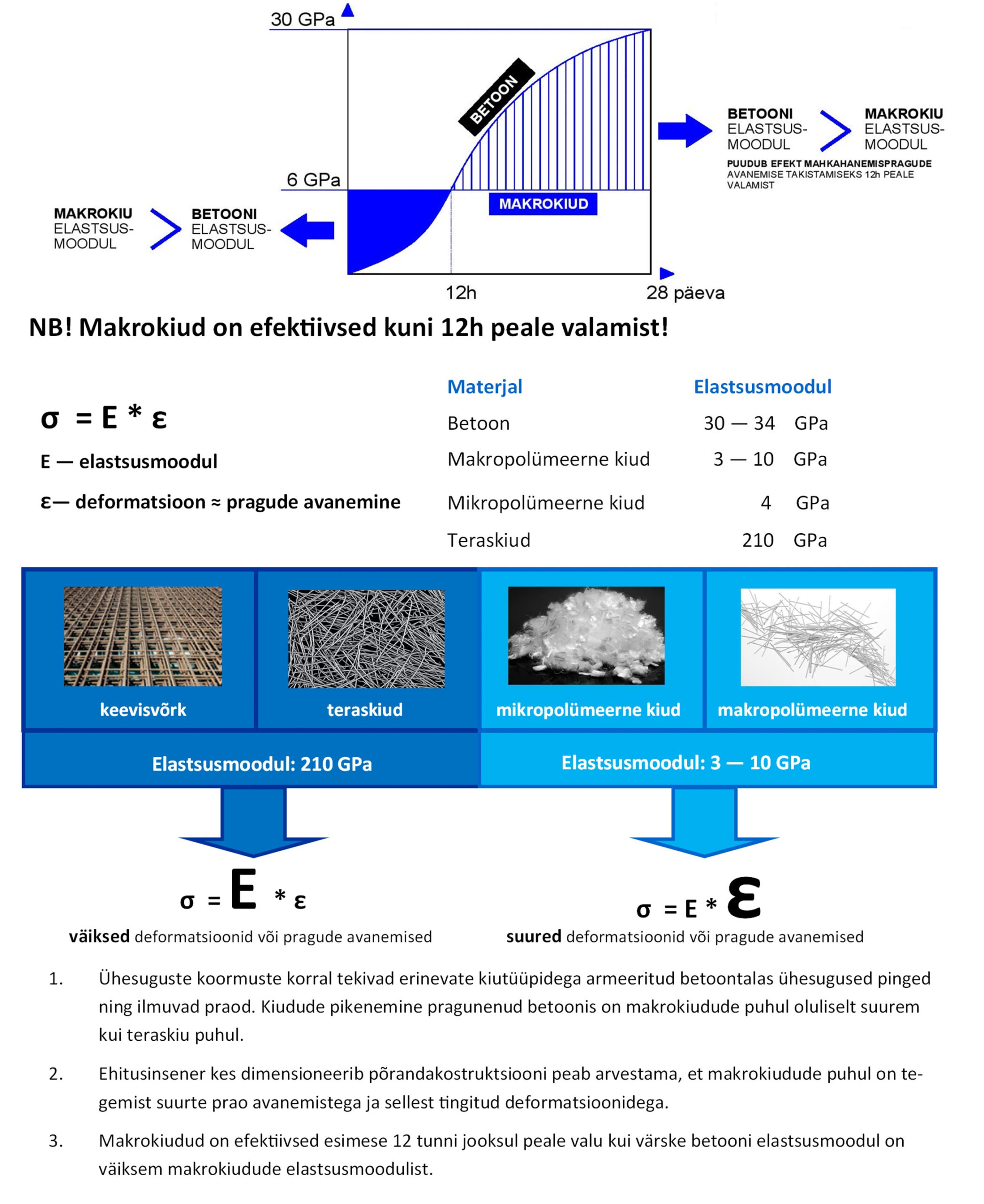

In terms of technical properties, macrofibers and steel fibers are very different. The way the fibers behave after cracking also differs greatly.

The main difference is that compared to steel fibers, the elastic modulus of macrofibers is approximately 40 times smaller.

Compared to concrete, the elastic modulus of macrofibers is approximately 5 times smaller, which means it is very difficult to prevent cracking with macrofibers.

Steel fibers start working immediately after microcracking, the maximum effect of macrofibers occurs when cracks open in the range of 1.5…3mm.

Macropolymer Fibers vs Steel Fibers:

Comparison of Fiber Reinforced Concrete (FRC) or Fiber-Reinforced Composite Material.

Material comparison