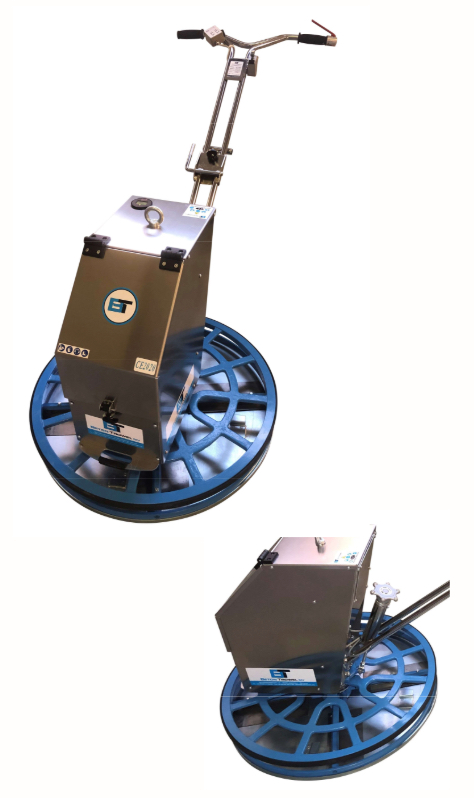

Tools – Battery Powered Power Trowels

Concrete construction is today one of the industries with the largest ecological footprint, and significant resources are therefore being invested in the development of new sustainable technologies. With the introduction of environmental certification for buildings, carbon footprint has become a critical KPI.

One solution for finishing concrete floors is to employ power trowels driven by high‑quality lithium‑ion batteries. Thanks to their zero‑emission operation, these units are essential from a work‑safety perspective in enclosed, poorly ventilated environments. They exhibit far fewer issues related to floor carbonation, and the noise level—which can disturb nearby personnel—is substantially lower.

Ideal for indoor use!

Equipped with a lithium-ion battery, this power trowel delivers:

- Safe operation with zero risk of carbon-monoxide exposure.

- Noise levels 70 % lower than petrol-engine models.

- Superior final finish thanks to higher machine weight, boosting work efficiency.

- Simplified operation—no refuelling procedures or associated costs; battery swaps are extremely fast and easy.

- Dramatically reduced maintenance expenses.

- Multifunctional LCD display showing blade angle, run time, battery charge level and blade-rotation speed.

Operable in manual mode, with the option to engage automatic control.

Specifications:

- Machine diameter: 610 mm

- Machine weight: 87 kg

- Battery weight: 21 kg

- Blade count: 4

- Motor power: 1.2 kW

- Maximum speed: 170 rpm

- Battery type: Lithium-ion

- Battery capacity: 60 V, 55 Ah

- Runtime: up to 180 min

- Charge current: 25 A

- Charge time (0 → 80 %): 90 min

- Foldable handle

Download product sheet:

Key Benefits:

- Emission‑free operation ensures a safe work environment in confined spaces, eliminating the risk of carbon monoxide exposure.

- No requirement to open doors or windows, reducing the risk of floor “curling” and shrinkage cracking.

- Eliminates the need for costly temporary forced‑ventilation systems.

- Low noise profile, crucial in densely populated urban projects.

- Zero fuel or oil‑change expenses.

- No risk of ground contamination from fuel spills.

- No uninterrupted power‑cord management; no tripping hazards or workflow interruptions.

- Quick battery swaps facilitated by a high‑capacity power port.

- Overall machine weight on par with gasoline models, allowing 1–3 hours of continuous operation under normal conditions.

- Rapid charger (230 V or 110 V) recharges a depleted battery in under three hours.